SmartBrief And RT3 Work Together To Promote Progressive Roofing Practices

Roofing Technology Think Tank (RT3), an emerging technology-focused group of roofing industry thought leaders, and SmartBrief, a leading digital media publisher of targeted business news, are seeing success with their partnership to promote technology throughout the roofing industry.

Launched December 11th, Roofing Technology SmartBrief powered by RT3 is a subscription-only publication that provides essential technology and diversity news and thought-leadership content three times a week to over 11,000 roofing professionals.

“Partnering RT3 with SmartBrief is one of the best ways to share the technology information that this group is curating and researching,” stated Dale Tyler of National Roofing Partners. “As a group, we are committed to the dissemination of information to the industry about technology advances and opportunities to improve the roofing process and business. Our goal is to have the entire industry receive these informative newsletters.”

RT3 is focused on serving the needs of the roofing industry with ongoing education, research, and dissemination of their findings. “The Roofing Technology Think Tank (RT3) is a consortium of thought leaders exploring emerging technology solutions for the roofing industry, striving to inform roofing contractors by bringing together progressive and disruptive solutions that help build the professionalism and appeal of the roofing industry,” is the mission statement for the group.

Learn more and subscribe to Roofing Technology SmartBrief powered by RT3. Additional information can also be found at https://192.241.168.40.

###

About Roofing Technology Think Tank (RT3)

Visualized by Dale Tyler of National Roofing Partners and Heidi Ellsworth of RoofersCoffeeShop.com and HJE Consulting, the Roofing Technology Think Tank (RT3) is a group of progressive roofing professionals focused on technology solutions for the roofing industry. The think tank strives to find innovative technology solutions to be used within the roofing industry. RT3 provides insights from progressive thought leaders both inside and outside the roofing industry along with practical resources for implementing potential solutions successfully. The organization will encourage and enable contractors to embrace technology as they seek to grow their businesses. With a commitment to disseminate technology and advancement of information, RT3 will help build the professionalism and appeal of the roofing industry. https://192.241.168.40

About SmartBrief

Serving nearly 6 million senior executives, thought leaders and industry professionals, SmartBrief is the leading digital media publisher of targeted business news and information by industry. By combining technology and editorial expertise, SmartBrief delivers the most relevant industry news – curated daily from thousands of sources – in partnership with leading trade associations, professional societies, nonprofits, and corporations. Using industry expertise and an engaged network of readers, SmartBrief’s content marketing offerings cut through the clutter and provide real solutions to targeted business needs.

By Dan Ciprari, CEO and Co-founder, Pointivo Inc.

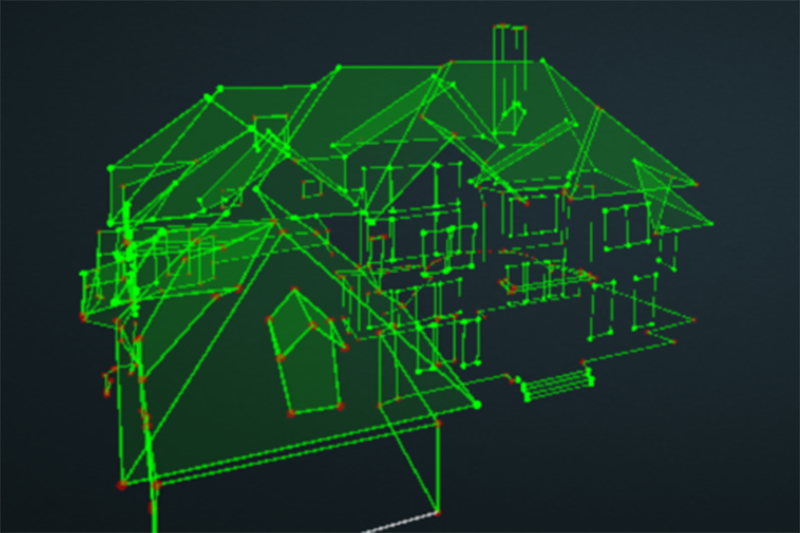

By Dan Ciprari, CEO and Co-founder, Pointivo Inc. Experienced field surveyors independently measured 13 roofs using traditional survey methods, while independent pilots flew autonomous Kespry UAVs over these roofs to capture images and generate 3D models.

Experienced field surveyors independently measured 13 roofs using traditional survey methods, while independent pilots flew autonomous Kespry UAVs over these roofs to capture images and generate 3D models.