By Nick Bean, Nearmap.

The basic skills of building, replacing or repairing a roof haven’t changed much in centuries. Improvements in materials—from thatch and wood shingles to slate and asphalt tiles—unfolded over this time. But rapid changes in technology- including updated aerial view maps – have helped roofers of every scale radically improve their businesses, and do it quickly.

Progressive roofing companies often use a blend of technologies these days. They might combine their standard practices with aerial measurement services to captures aerial views from 15°-45° (a.k.a., “oblique”) angles and top-down (or “orthogonal”) perspectives. Or they might purchase roof-measurement reports or decide to deploy deploys drones to provide visual information.

All that is fine—provided the roof of your target customer isn’t obscured by trees, limiting your prospecting to a relatively small area and resulting in inaccurate measurements. As you might imagine, many reports are not based on leaf-off imagery, the best satellite maps lack detail, and drones are typically flown on demand, regardless of foliage conditions.

Unfortunately, roofers have tight windows of opportunity to operate. They can become busiest right after a hurricane, a tornado, a hailstorm, or heavy snow coupled with high winds. Your lines may be flooded with calls from damage-sustaining households across a wide area. Even in good conditions, roofing companies are required to continuously prospect, estimate and quote with detailed measurements as they compete for business, one street and neighborhood after another.

In a highly competitive business, roofers need every edge they can get. Prospective customers want accurate repair quotes—and they want them quickly. So why wouldn’t you choose a tool that can give them both and, at the same time, enable you to accelerate your business?

High-resolution aerial imagery, captured multiple times per year offering leaf-on and leaf-off views, gives roofers exceptional perspective and a distinct advantage over many competitors. If that information can be instantly accessed from any laptop, mobile or connected device, all the better.

How does this razor-sharp information help you in your business? After a catastrophe, a roofer’s time is scarce. Every hour traveling from one job location to another eats up this precious time when you could just as well identify new prospects in minutes from your desktop. With high-definition aerial imagery, you can instantly scan thousands of rooftops at a tap or a click of the mouse. With a couple of clicks you can switch from vertical to panoramic to oblique views and swiftly identify roofing opportunities.

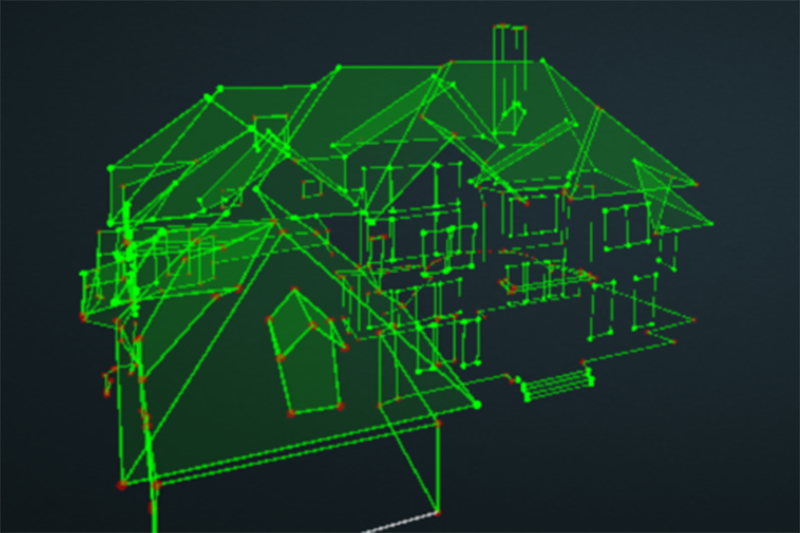

The most sophisticated visual tools are now available to everyone that let you generate precise measurements of rooflines and areas. Using an oblique feature, you can compare different roofs for accurate estimates of pitch. With some imagery software you can also annotate sections of the images—noting, for example, severe damage in a given corner, the need to pay particular attention to an especially steep area of the roof, or an area of the property with easy access to unload roofing materials. (Of course, you can check these calculations when you visit the site.)

Saving countless hours, operating from the convenience of your office, you can create dozens of accurate estimates per day, as well as get a fix on your underlying costs since you have all the visual information you need right at your desktop (or tablet or mobile device). And you can generate a visually stunning, highly accurate quote for prospects: they can see the damage up close and immediately grasp the extent of necessary work. That sort of presentation builds confidence—an advantage many of your competitors probably can’t offer. You build trust and are more likely to get a Yes or No from a customer on the spot.

The advantages of aerial imagery include not only leaf-off and leaf-on perspectives. Now roofers can easily navigate from vertical top-down perspectives to oblique angles while measuring height and width of the buildings and roofs. With easy and cost-effective access to rich, high resolution maps, you can work faster and smarter—and thereby increase your business. It’s a vital service whether you’re a large contractor, a midsize organization, or a mom-and-pop outfit with just a couple of employees.

Roofing may be an ancient profession. But to stay in business, you need every available advantage—today’s aerial imagery saves time, lowers costs, and may well be your most productive resource.

Note: This article first appeared on RoofersCoffeeShop.com blog and can be viewed here.

By Dan Ciprari, CEO and Co-founder, Pointivo Inc.

By Dan Ciprari, CEO and Co-founder, Pointivo Inc. Experienced field surveyors independently measured 13 roofs using traditional survey methods, while independent pilots flew autonomous Kespry UAVs over these roofs to capture images and generate 3D models.

Experienced field surveyors independently measured 13 roofs using traditional survey methods, while independent pilots flew autonomous Kespry UAVs over these roofs to capture images and generate 3D models.