By Malek Murison.

Drones are not like mobile phones. Ideally, you don’t want to be buying or upgrading to a new model every year. Instead, look at it as an investment in your aerial photography skills: the best way to reap the rewards is to keep your drone in great shape and performing to the max for as long as possible.

Think about coverage

The first thing you should do after buying a new drone is to organize some kind of cover. Things can (and probably will) go wrong at some point. The last thing you want is for your $1,000 gadget’s value to plummet down to $0.

Your best way to stop that from happening is to arrange insurance. Better still, most manufacturers offer coverage for the first year. For example, DJI’s Care Refresh package can be bought alongside a new drone to give you peace of mind and practical support in case you crash or damage your drone.

The company will attempt to get it working again or supply you with a new model.

Keeping on top of pre-flight checklists

Once that first year is through, most coverage policies will run out and regular insurance will be your best bet.

But besides that, you can extend the life of your drone by developing a flight routine based on care and accident prevention.

The best way to do that is to stick rigorously to a comprehensive pre-flight checklist. Keep on top of the status of your drone and avoid flying if there are any obvious problems or faults.

Keeping your drone safe when it’s not in use

As a drone pilot, one of the most frustrating things that can happen is your gear getting damaged when it’s not even in use.

Taking care when charging, installing updates and storing your drone is the best way t stop that from happening. Find as sturdy a case as possible to store your drone, and keep it out of the way of kids, pets and the elements.

Looking after drone batteries

A question plenty of pilots have is how to extends (or at least maintain) the life of drone batteries. Every second counts when you’re up in the air, so keeping your batteries performing to the max is essential.

Most drone manufacturers state that lithium polymer batteries should be stored at a temperature of between 5ºC and 27ºC. The lower the temperature the better, in fact. If they are being packed away for the long term, battery experts recommend making sure they have around 40% of charge.

When it comes to charging, the most common way to damage a LiPo battery is by overcharging it. So once your batteries hit 100%, unplug them. Experts also suggest that letting your battery drain to 0% on a regular basis will reduce its life in the long term.

Buying new batteries for your drone is usually an expensive process. Taking a few easy steps can help keep yours in good condition.

Practicing in something expendable

The majority of crashes and accidents happen when drone pilots are new on the scene or when complacency creeps in. So the best way to keep your valuable gear intact is to grow in confidence and gain more experience behind the controls.

For those in the former category, it’s a good idea to try your hand at flying something cheaper and relatively expendable. There are plenty of drones for beginners out there that won’t break the bank. You can also check out our post on the common mistakes drone pilots make to learn from the mishaps of others.

Interested in finding a drone that can extend your flight time, too? Check out this rundown of which drones stay in the air for longest.

Note: This blog first appeared on RT3 member Drone Base’s blog and can be viewed here.

By Dan Ciprari, CEO and Co-founder, Pointivo Inc.

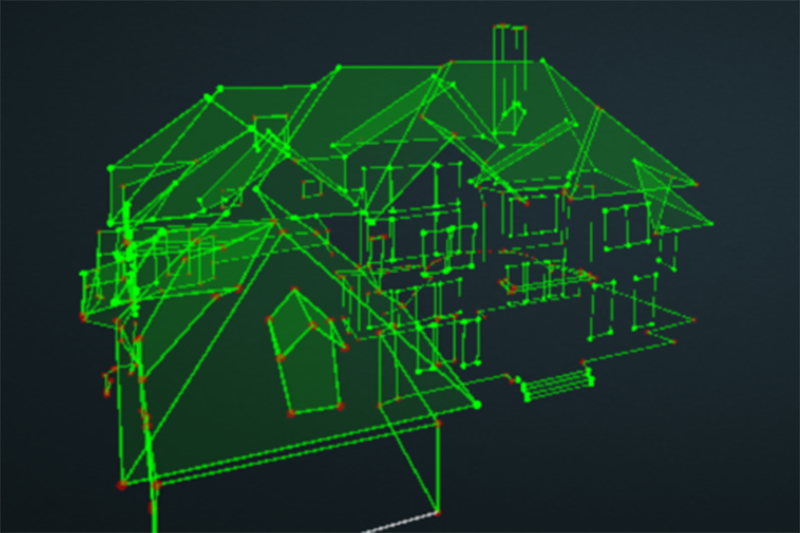

By Dan Ciprari, CEO and Co-founder, Pointivo Inc. Experienced field surveyors independently measured 13 roofs using traditional survey methods, while independent pilots flew autonomous Kespry UAVs over these roofs to capture images and generate 3D models.

Experienced field surveyors independently measured 13 roofs using traditional survey methods, while independent pilots flew autonomous Kespry UAVs over these roofs to capture images and generate 3D models.